| Type of Company | Manufacturer |

| Performance: | Eco-Friendly |

| Application: | Air-conditioner ,container ,automobile ,Industry. |

| Certification: | ISO9001 |

| Production Capacity: | 200 Tons/month |

| Trademark: | YUKE |

| Origin: | WUXI China |

| Language: | Remaches, Rebites |

| QC (inspection everywhere) | Self-check through production |

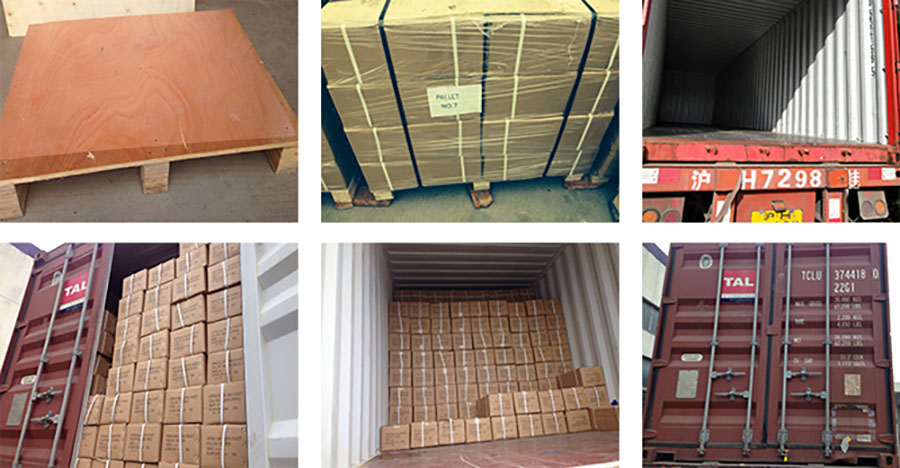

| Transport : | By sea or By air |

| Payment Terms: | L/C, T/T, Western Union |

| Port: | Shanghai , China |

| Lead Time : | 15~20 Working Day for A 20' Container |

| Package : | 1. Bulk packing: 20-25kgs per carton. 2. Small color box,: color box, window box, polybag, blister. Double shell packing or as clients’requirement. 3. Assortment in polybag or plastic box. |

| Material: | Aluminum Body/Aluminum Stem |

| Surface Finishing: | Polish/Polish |

| Diameter: | 3.2mm, 4.0mm, 4.8mm, 6.4mm,(1/8, 5/32, 3/16,1/4) |

| Customized: | Customized |

| Standard: | IFI-114 and DIN 7337, GB.Non-standard |

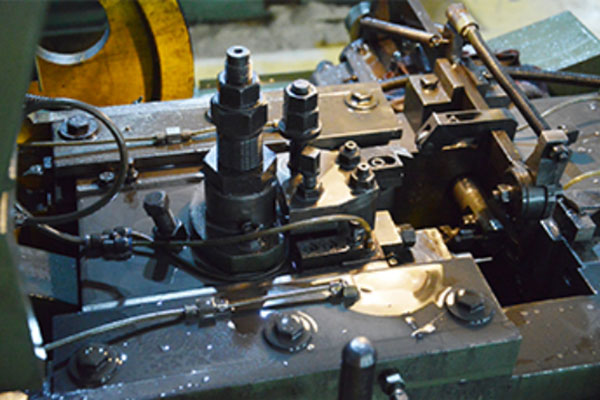

• Design assistance and full engineering support • One stop manufacturing includes sourcing of subcomponents and hardware overseas partners •Complete production lines for custom turning, milling, cnc machining sheet metal stamping, bending, argon welding and surface finish. • Anodize and power coating finish with all kinds of customized colors. • Strict quality control standards with a highly qualified inspection department. •Continually upgrading and advancing our equipment to remain competitive. •Extensive capacity — We can run 24 hours, 6 days a week. •Our main goal is TOTAL CUSTOMER SATISFACTION while making your job easy!

• Design assistance and full engineering support • One stop manufacturing includes sourcing of subcomponents and hardware overseas partners •Complete production lines for custom turning, milling, cnc machining sheet metal stamping, bending, argon welding and surface finish. • Anodize and power coating finish with all kinds of customized colors. • Strict quality control standards with a highly qualified inspection department. •Continually upgrading and advancing our equipment to remain competitive. •Extensive capacity — We can run 24 hours, 6 days a week. •Our main goal is TOTAL CUSTOMER SATISFACTION while making your job easy!